Manufacturing with laser light

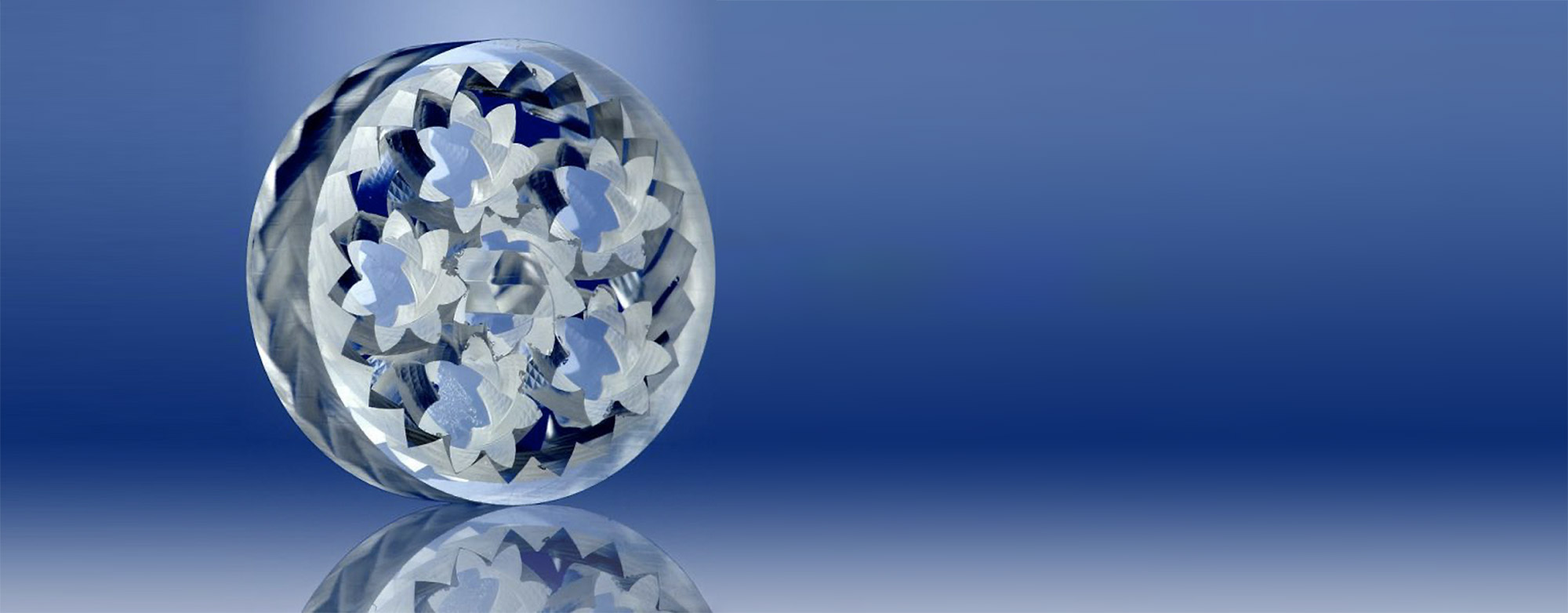

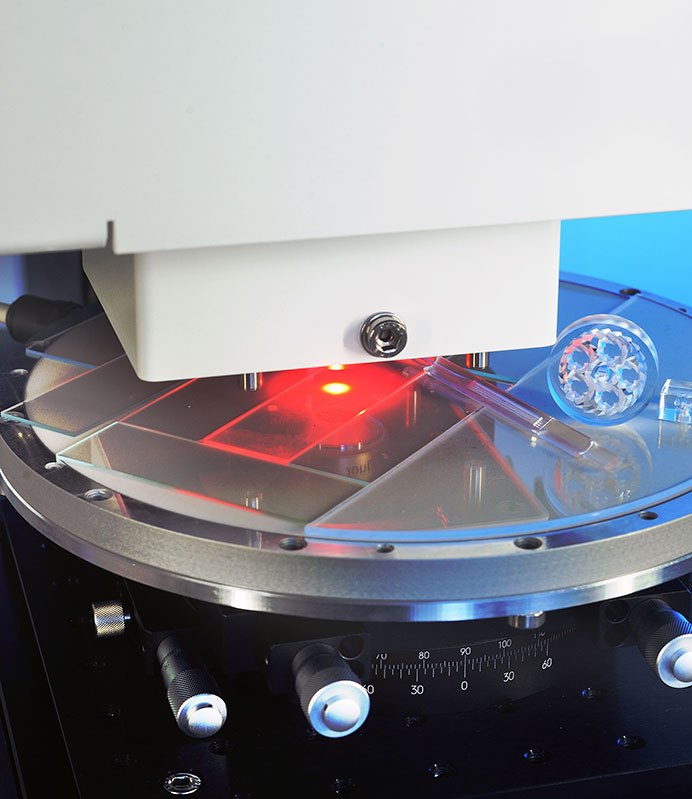

We produce microstructured glass components using ultrafast laser radiation, as well as the microscanner suitable for their productive production – the “LightFab.” The founders (Dipl.-Phys. Martin Hermans, Dipl. Ing. Jürgen Ortmann, and Dr. rer.nat. Jens Gottmann) have many years of experience with the ISLE process, in the development and use of microscanners, and their unique experience in software development for scanner and system control form the basis for our innovative products.

Our goal is to make the processing of transparent materials with high-performance ultrafast lasers widely used.

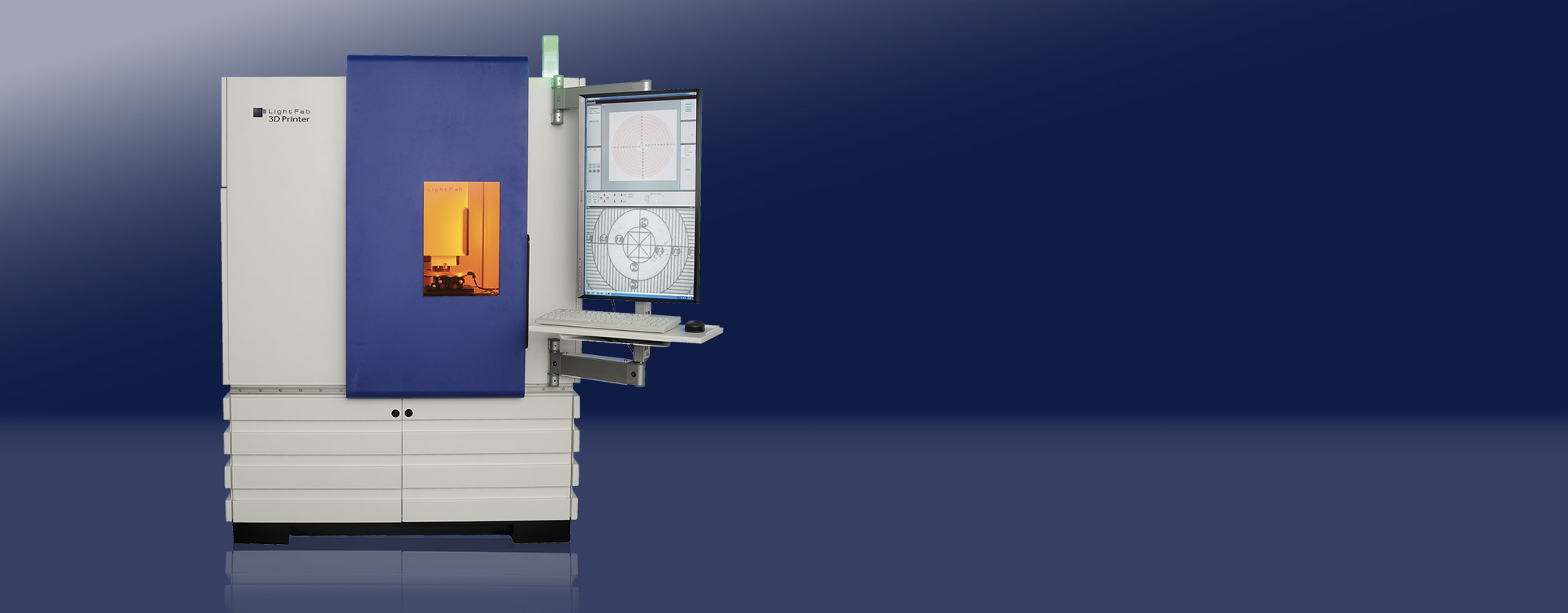

LightFab – 3D production with light.

News

- New project: Fort OP

More information will follow soon.

- Compamed 2025

17.-20.11.2025

Düsseldorf, Germany

Exhibition hall 8A

stand F19-8 - Photonics West 2026

17.-22.01.2026

St. Francisco, California

Booth 4205 33

in the German Pavilion

Products & Technologies

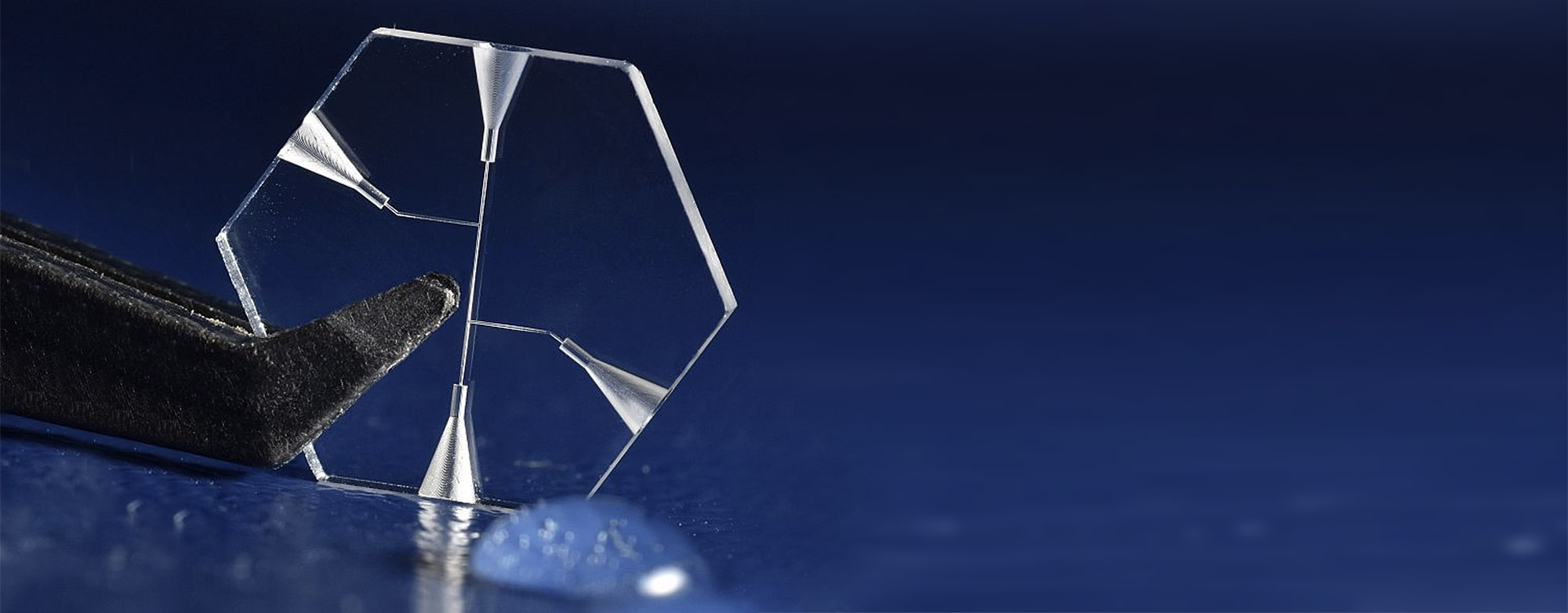

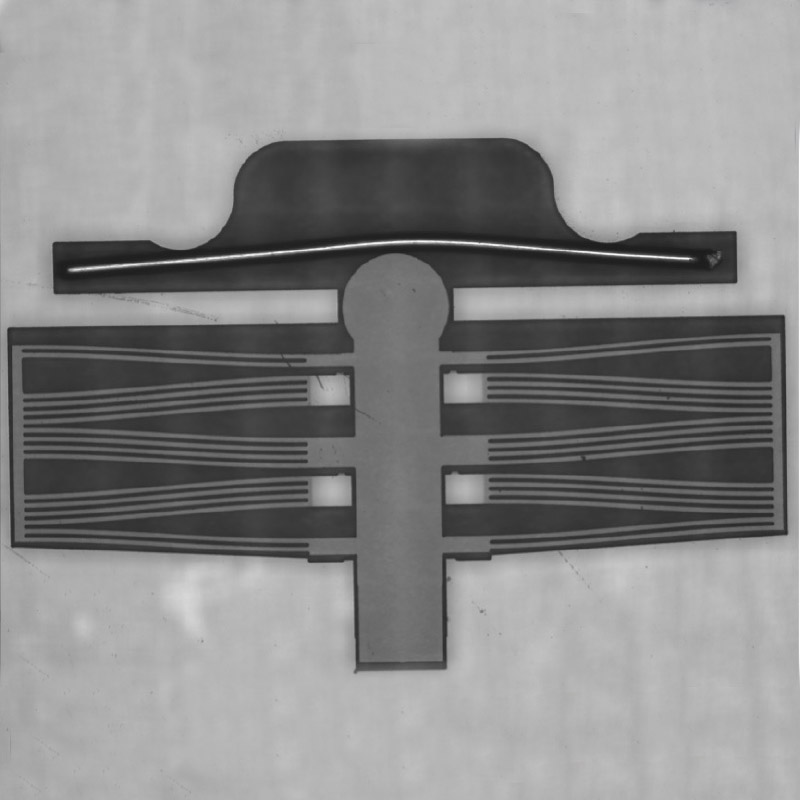

Mechanical functions

Spring mechanisms

Fiber clamps

Gripper functions

Rotary mechanisms such as gears

Counters for temperature exceedances

Couplings & adapters

Passive alignment (microbench)

Aero- and Hydrodynamic Functions

Pick & Place – tools

> Vacuum grippers

> Vacuum microbench

Nozzles

> Laval, swirl bodies, etc.

Mixers

Custom suction plates

> With internal 3D elements

> With precisely fitting stops on the surface

Cavities filled with gas or under vacuum

Products under mechanical stress

Glass injection molds and impression molds are resistant to temperature and pressure.

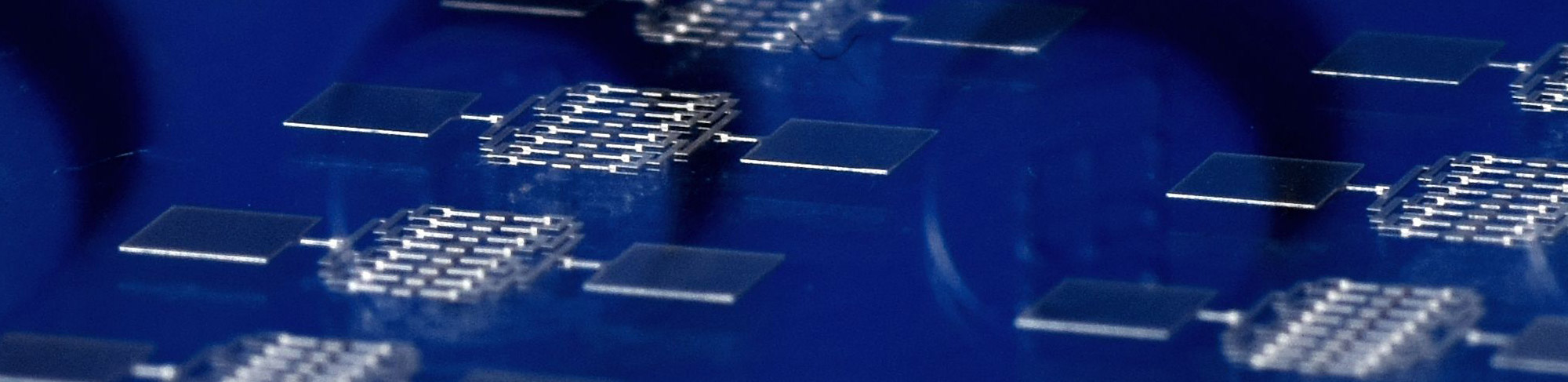

Compared to conventional manufacturing processes, designs can be produced quickly and cost-effectively using SLE 3D printing.

Piston housings and cylinders for micropumps.

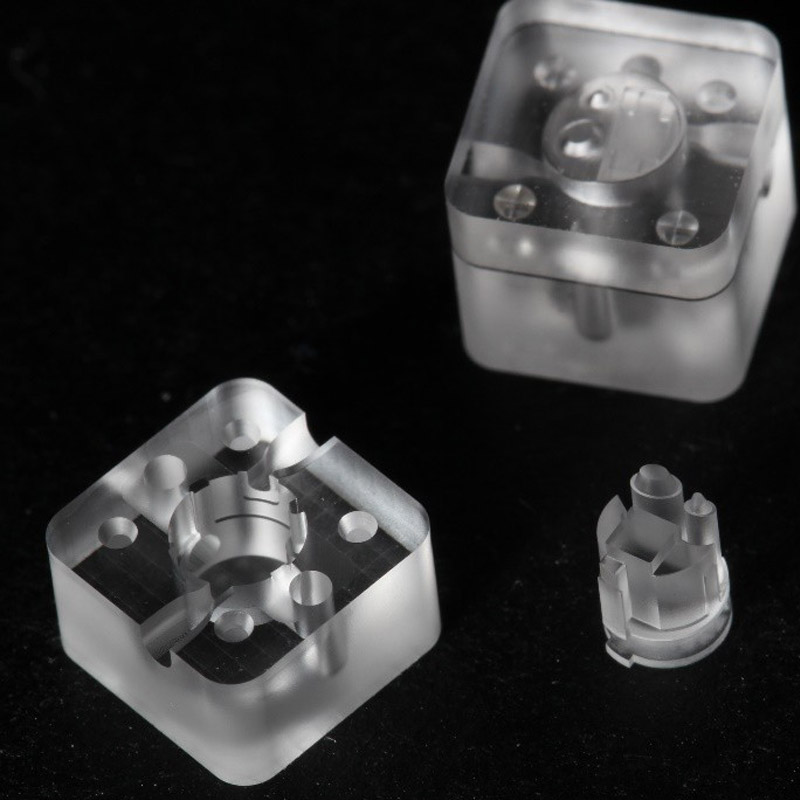

Micro-Fluidic

Microchannels with constrictions, branches, and connector elements (threads, Luer, etc.) in all three spatial dimensions.

The patented LightFab welding process allows even the smallest microstructures to be combined with elements in the macro and millimeter range. This gives you a high degree of design freedom while maintaining high precision in the micrometer range.

About LightFab

LightFab GmbH is a young technology company in the field of laser technology.

We started LightFab in 2013 and developed the foundations of our technologies at the Chair of Laser Technology at RWTH Aachen University, located at the Fraunhofer Institute for Laser Technology ILT in Aachen.

We produce microstructured glass components using UKP laser radiation.

Our innovative products are based on many years of experience with the SLE process, the development and use of microscanners, and our unique expertise in software development for scanner and system control.

Our goal is to bring the processing of transparent materials with high-performance UKP lasers to a wide range of applications.

Contact

Please fill out the following form and send us your request. We'll get back to you as soon as possible.